INNOVATION · VERSATALITY · TRADITION

Get In Touch: (315) 454-8608

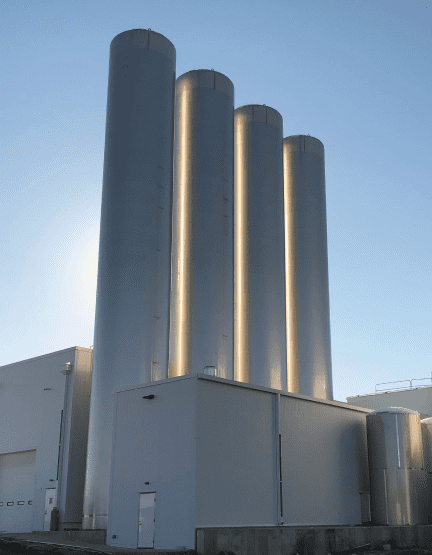

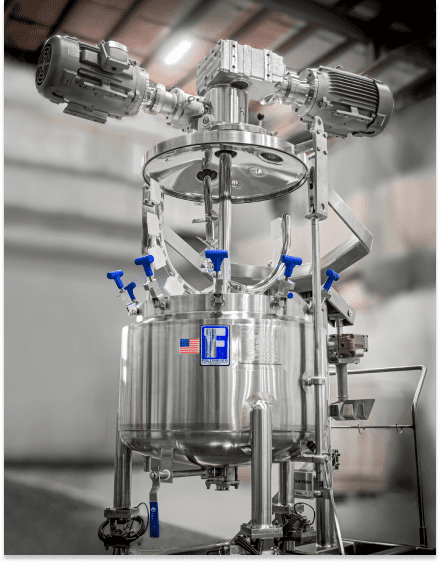

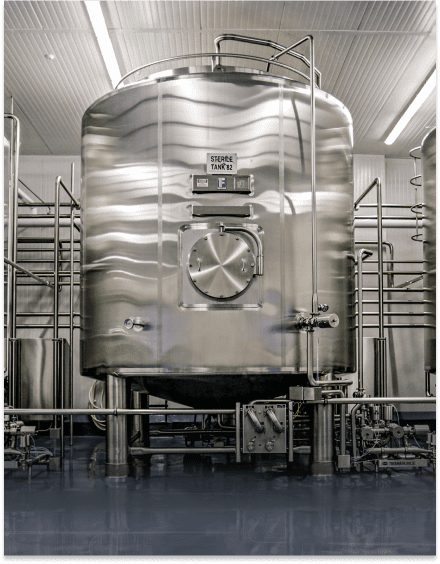

Your Expert in Stainless Steel Tanks, Vessels & Custom Fabrication

Feldmeier Equipment fabricates a variety of stainless-steel tanks and pressure vessels, including storage, mixing/blending, processing, reactors, and custom-designed solutions, providing you with the

equipment you need to make your project a success.