Inspection Services for Stainless Steel Tanks & Vessels

In-house Inspections and service for existing equipment

- Visual inspection – in accordance with ASME Section VIII

- Liquid Penetrant Testing (LPT) – in accordance with ASME Section V

- Borescope Inspection – in accordance with ASME Section VIII and ASME BPE

- Surface Finish/Roughness Inspections in accordance with applicable standards and customer specifications

- Ultrasonic Thickness Inspection

- Positive Material Identification (PMI) – using XRF (X-Ray Fluorescence) to confirm material type

- Wipe Test Inspection

- Tank Integrity Testing – preventative inspection on in-service equipment

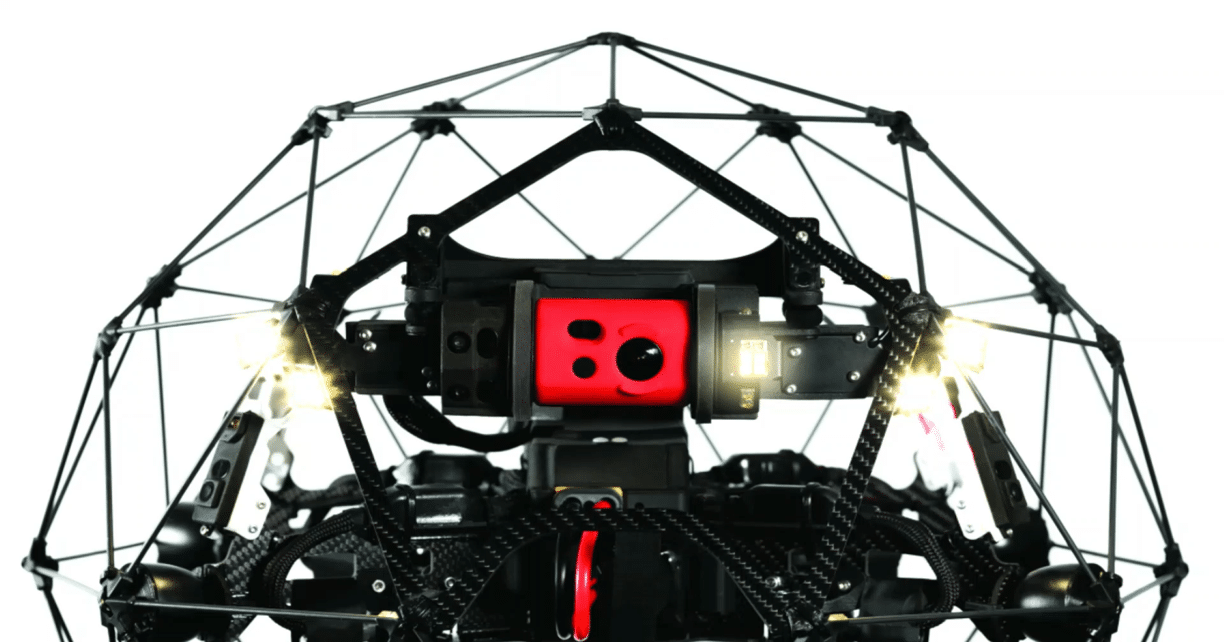

Drone Inspection

A method of performing visual and thermal inspection where access is restricted typically due to elevation and confined space entry.

- Eliminates confined space entry for inspections, saving down time and cost

- Inspect any size vessel without the threat of harming surfaces

- Capture 12 MP images and 4K video of tank internals

- Links images to precise locations within 3-D point clouds

- Performs 2-D measurement within video post-processing analysis

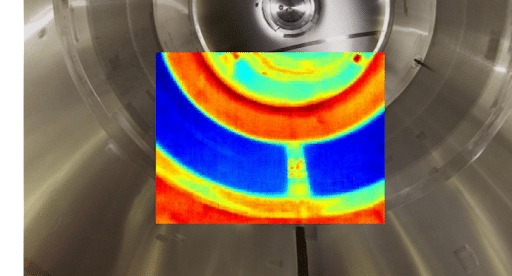

- Collects thermal imaging and video

- Inspects welds, surface finish and in-tank components, such as agitators

- Allows for early detection of cleaning issues or corrosion