Factory Inspection Testing (FAT) & Site Acceptance Testing (SAT)

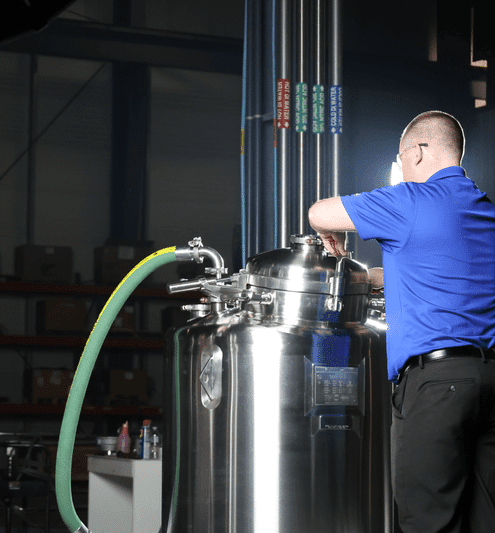

Feldmeier recognizes that a successful startup must accompany your shipment. To ensure a smooth receipt and startup, we are pleased to invite you for an in-process inspection of your equipment, as well as pre-shipment Factory Inspection Testing (FAT) at completion. Site Acceptance Testing (SAT) support options are also available.

Feldmeier exceeds the quality and documentation requirements necessary to help our customers achieve Installation, Operation & Performance Qualifications to satisfy regulatory agencies and their clients, ensuring a smooth review and validation. All testing will be verified prior to shipping, documented and sent in the final vessel manual if required.

- Dedicated in-house staffing for FAT

- Inspection support for all applications, specializing in Pharmaceutical markets

- Standard or custom test protocols available

- Dimensional checks

- Surface finish testing

- Material UT thickness and Positive Material Identification (PMI) testing available

- Riboflavin CIP unit testing

- Agitator “wet” testing

- Drainage testing

- De-ionized water for all wet testing and final cleaning after passivation

- Certified testing equipment traceable to NIST standards